Penn State University (#us75)

A half scale post mill built in 2004 by the Center for Medieval Studies, in association with their April 2004 conference Wind and Water: the Medieval Mill. Later relocated from the Medieval Garden, to the Center for Sustainability.

Since the pages that described the project have not been present on the web for many years, I have taken the liberty of extracting chunks of their content and illustrations from a cached copy below:

The Molinellos (Italian term for "windmill")

Group Members

John Stella, Abby Thornbury, Megan Pomeroy, and Chris Esterly

Four mechanical engineering students at Penn State University enrolled in the senior capstone class in the fall of 2003. Our project was with the Science, Technology, and Society Program to develop a postmill for educational purposes at Penn State.

Engineering Analysis

Summary

A demonstrational medieval post style windmill is to be erected to compliment the current medieval gardens on the Pennsylvania State University campus. These group of four mechanical engineers called the Molinellos designed and prepared engineering analysis for the new windmill. Researching post windmill designs, corresponding with people who built post windmills, and visiting a post windmill in Williamsburg, VA established a foundation for the authenticity of the design. Knowledge of fluid mechanics, machine design, strength of materials, and static forces was applied in the engineering analysis to ensure the windmill?s functionality and stability. A force analysis on the structure was carried out by hand to ensure stability and determine the proper materials to be used in construction. The group will present the sponsor, Steve Walton with a SolidWorks model, a scale model of the windmill, results of engineering analysis, as well as a cost estimate for materials and construction.

The design specifications and analysis were broken down into several key areas of design interest:

- sail design

- windshaft bearing and gear design

- crowntree analysis

- structural design

These four areas of the post mill were constructed during the medieval period (1200 to 1700 AD) with a method of trial and error. Now in the 21st century, we have the tools and the engineering principles to justify the reasonings behind having the main post being closer to the breast(or front), the loading the crosstree can endure, the gear ratio, and so on. Our analysis included many of the basic principles taught in engineering classes, like fluids, statics, machine design, etc.

Sail Design

The average density of air for state college is 1.22 kg/m^3. (Accuweather). The optimal operational wind speed is estimated at 18 miles per hour or 8.05 meters per second. The total surface area of the sails is calculated to be 44.23 meters. The efficiency of the system for a post windmill is assumed to be 0.2 (Redford 20). The maximum power produced by the windmills is 2.81KW.

Windshaft, Gearing, and Bearing Design

Historically the shaft was most often made out of white oak. The materials for the gears, however, varied. Spruce was selected for the structural part of the gear because it is approximately 65% lighter than white oak. This will result in less rotational mass in the shaft as well as less weight for the overall structure. Hickory, a much harder wood, was chosen for the gear teeth because of its increased strength and wear properties.

Crosstree

The crowntree rests upon the main post and is responsible for supporting the weight of the entire structure of the windmill. The maximum shear force, bending moment, bending stress, and shear stress were calculated at the crowntree. By finding the maximum allowable values the wooden materials were capable of withstanding, we were able to determine the amount of material for the crosstree required to withstand such loads. From our structural analysis of the crowntree a few new options have been developed. If large timbers are unable to be used we will look further into the use of steel I-beams. In an attempt to keep the authentic feel of wooden structural elements it would be possible to construct a mask to cover the steel beam.

Another material option for the construction of the crowntree would be to incorporate laminate materials which will enable us to reduce the amount of large solid structural members needed, reducing the overall production cost.

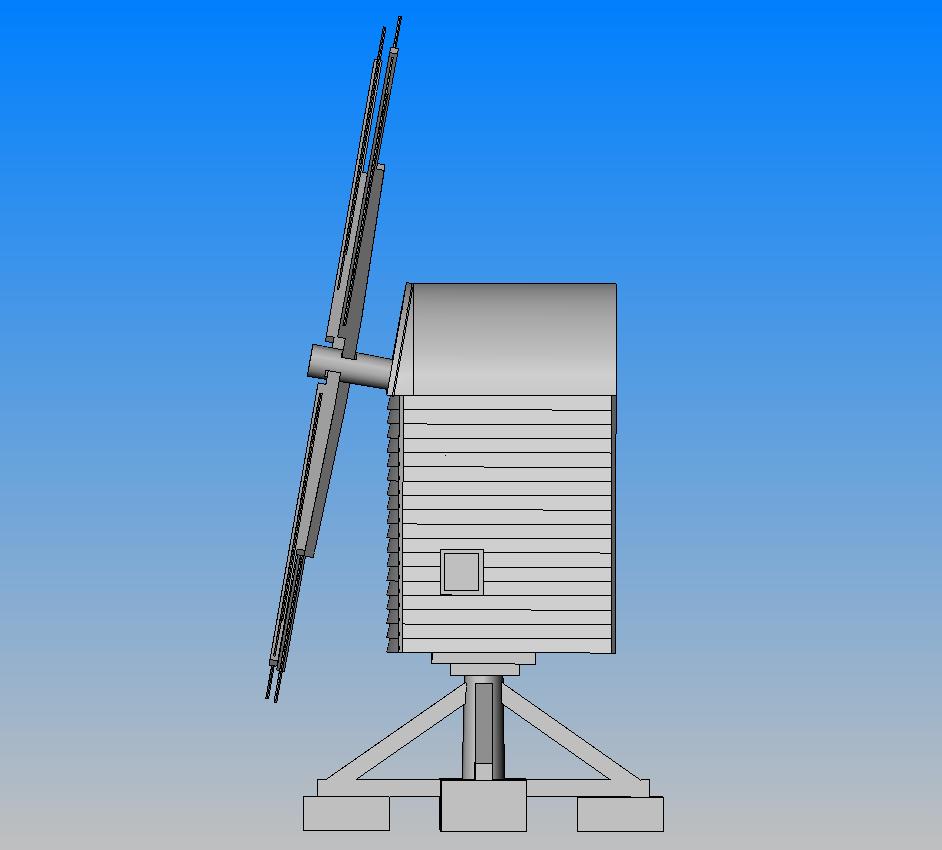

[photo]Design of the postmill

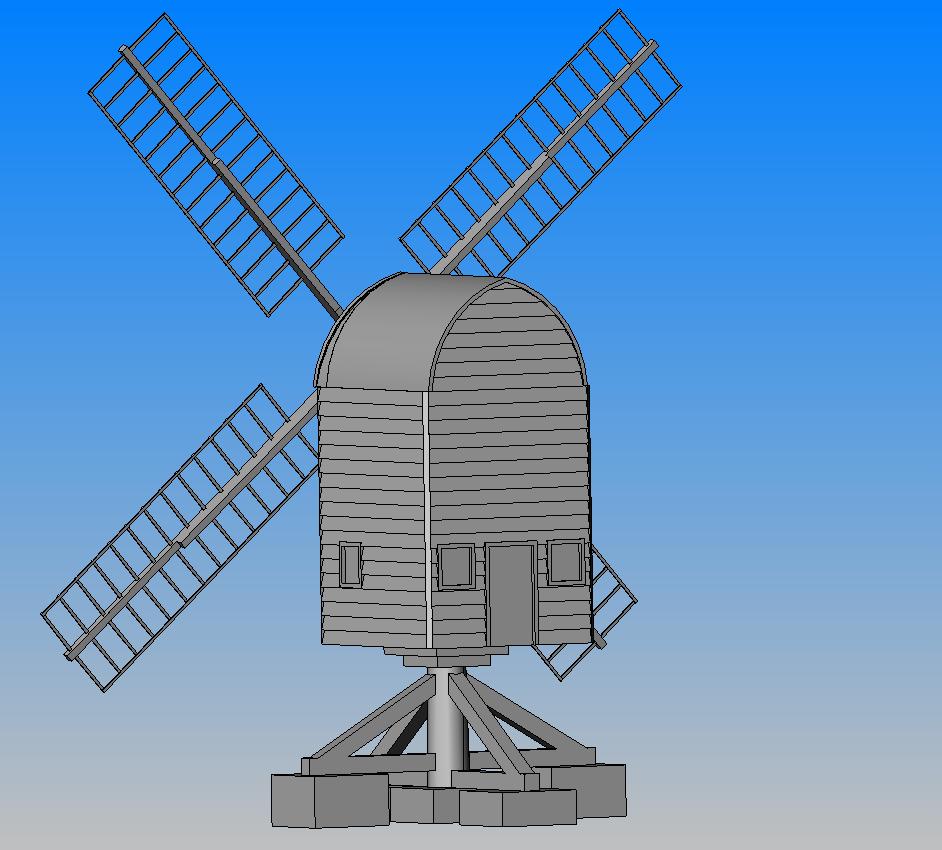

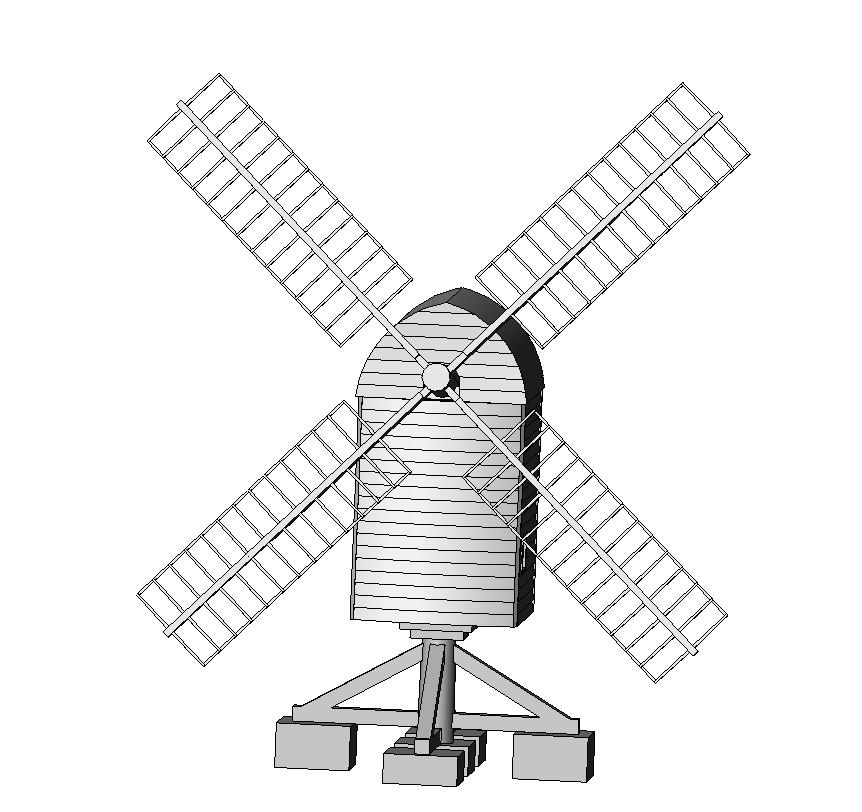

The Molinello's postmill was based off the Robertson Postmill in Williamsburg, Virginia. For the postmill to have originality, we kept the high arched roof which was common during the medieval period.

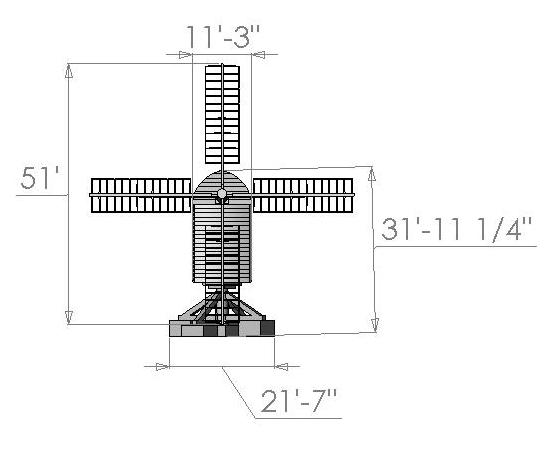

Below you can see the SolidWorks models and our prototype used to show the design of the postmill. The overall dimensions are shown. The postmill constructed may be a 1:2 scale.

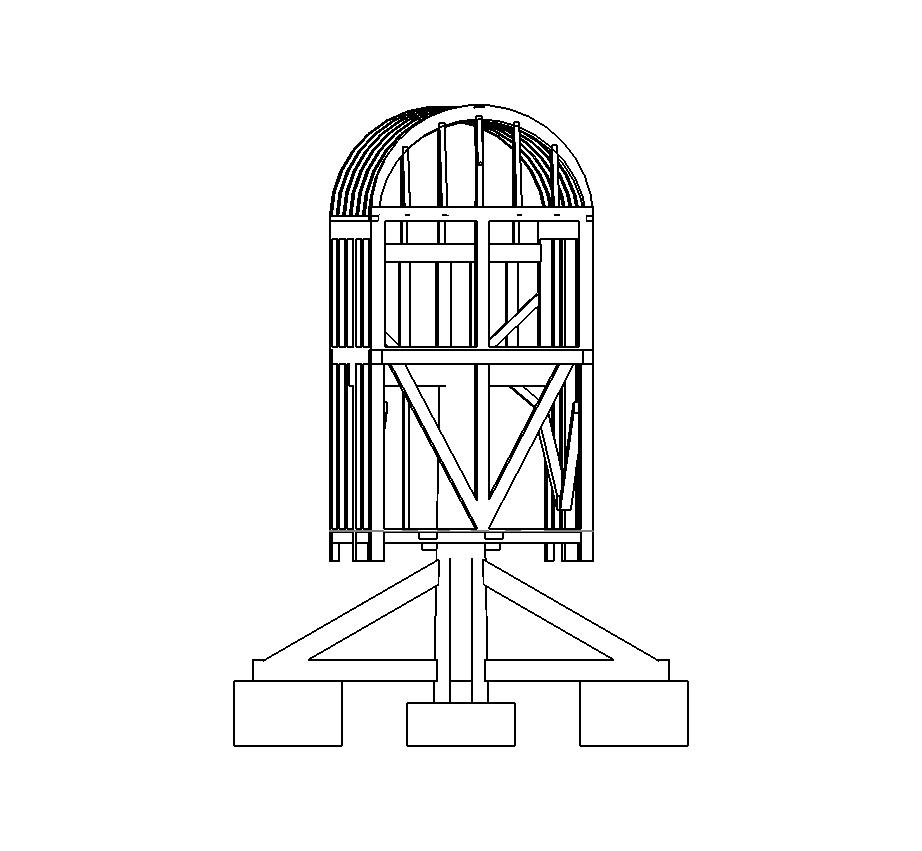

The frame of the structure.

Back, front, and side views

Prototype